Engineering Solution

End to End Engineering Solutions

Over the years, BSTO has tackled numerous challenging problems, honing our ability to transform complex issues into innovative solutions. Today, we offer a wide range of engineering solutions and excel in stamping tool design and development, robotic tool design and development, manufacturing process studies and simulation, as well as plant, process, and layout simulation services.

At BSTO, we prioritize reducing manual labor wherever possible to enhance productivity, precision, and quality. This commitment has enabled us to pinpoint areas requiring improvement and deliver customized automation solutions to fulfill productivity and business needs. Our team possesses the expertise to implement automation solutions across assembly line setup, robotic welding projects, robotic pick-and-place projects, and a multitude of turnkey automation projects. We take pride in our competent and dedicated teams, capable of developing, executing, and deploying all necessary elements to fulfill the organization’s requirements.

Tool Design & Development

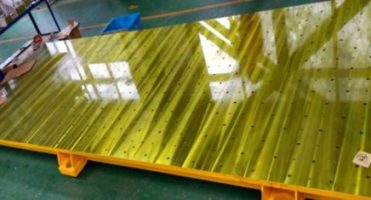

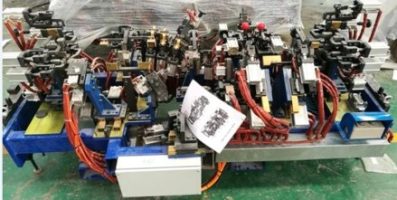

Tool Design & Development

Our metal blanking tool development is one of the many capabilities that BSTO possesses to strive forward in its commitment of satisfying its customers in all the possible ways that we can. BSTO tool room engineers are experts in providing Metal Stamping Tools of various parts from the smallest intricacies to the largest complexity. Our experts utilize different technologies at their disposal to ensure that the finish of the material is retained even after the operations.

OUR CAPABILITIES

- Testing

- Automated Systems

- Mechanical Systems

- Modification and Optimization

- Commissioning & Start-up

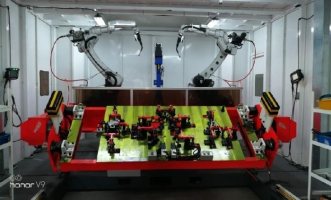

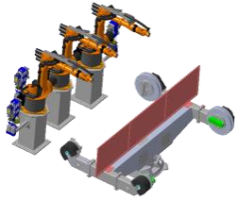

Robotic Tool Design & Development

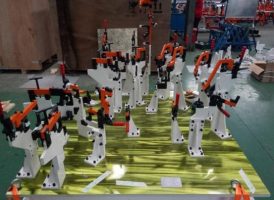

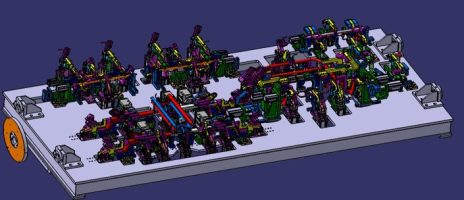

Robotic Tool Design & Development

Our robotic tool design team is an expert in complex robotic tool design which is the heart of any robotic system specifically designed for an application or product handling. This team employs a rigorous methodology to design and develop solutions to meet the most complex production challenges. Feasibility assemblies are taken into consideration to ensure that the conceptually designed tools are able to handle parts in repetition and with perfect accuracy.

OUR CAPABILITIES

- Testing

- Automated Systems

- Mechanical Systems

- Modification and Optimization

- Commissioning & Start-up

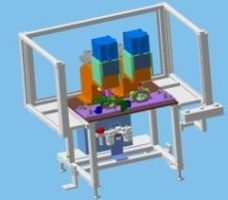

Manufacturing Process Studies & Simulation

Manufacturing Process Studies & Simulation

BSTO in its three decades of existence has developed its own indigenous capabilities, technological tools and methods for successful implementation of innovative manufacturing processes that allows for the experimentation and the validation of products and process & systems design.

OUR CAPABILITIES

- Manufacturing Networks Planning & Control Planning & Verification

- Factory Layout Design

- Material and Information Flow Design

- Manufacturing Networks Design

- Manufacturing Systems Planning & Control

- Manufacturing Networks Planning & Control

- Planning & Verification

Plant, Process & Layout Simulation Services

Manufacturing Process Studies & Simulation

Our more than three decades of experience in the field of production and manufacturing had helped us evolve us into competent officers of simulation services to visualize, validate and improvise to improve designs of a plethora of manufacturing system.

OUR CAPABILITIES

- Throughput Analysis & What If Analysis

- Cycle time analysis

- Workforce Planning and Workspace Analysis

- Facility planning and Plant Utilization

- Manufacturing Networks Planning & Control

- Tool & Equipment Setup

- 3D Model Layout

- Operator Walk paths and Robot Envelope

- Perimeter Fencing, Control Panels & Enclosures

Weld Penetration set up with Microscope